Aluminum Chlorohydrate (ACH) is a high-basicity inorganic polymer coagulant made from refined industrial aluminum ash and activated bauxite.

Compared with Basic Aluminum Chloride (BAC), ACH has higher alkalinity, more hydroxyl groups, better solubility, and faster flocculation, making it ideal for drinking water, industrial wastewater, and advanced purification systems.

| Item | Specifications | Results |

| Appearance | Clear to slight hazy liquid | Slight hazy liquid |

| Alumina(Al2O3) % | 23 - 24 | 23.42 |

| Chlorides(Cl) % | 7.9 - 8.4 | 8.16 |

| Atomic ratio(Al:Cl) | 1.90:1 - 2.10:1 | 1.99:1 |

| Basicity % | ≥80 | 83 |

| Sulfate (SO42-) ppm | ≤250 | Not detected |

| Iron(Fe) ppm | ≤150 | 79 |

| Arsenic(As) ppm | ≤2 | <2 |

| Heavy metals % | ≤0.001 | <0.001 |

| Specific Gravity (20℃) g/ml | 1.330-1.350 | 1.336 |

| PH value(30% w/w) % | 3.8-4.7 | 4.3 |

| Conclusion: This product conforms to the requirements of USP-34 Specification. | ||

Solid: 25kg paper bag (lined with PE inner membrane bag)

Liquid: 200L plastic drum/1000L IBC drum/14-24m ³ container liquid bag

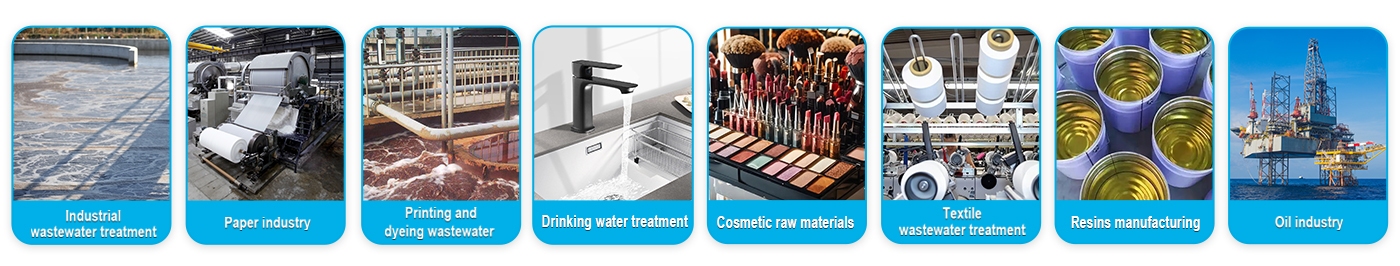

Aluminum Chlorohydrate (ACH) is an efficient inorganic polymer coagulant with high basicity, strong adsorption capacity, and excellent stability. It is widely used in:

Drinking water purification, industrial wastewater treatment, paper making, dyeing, and electronic water systems. Its high purity and low residual characteristics make it ideal for advanced water treatment applications.

1. ACH should be stored in a cool, dry, and well-ventilated area, protected from moisture and direct sunlight.

2. Liquid ACH should be kept in corrosion-resistant plastic or fiberglass containers with tight sealing.

3. The recommended storage temperature is between 5°C and 30°C, avoiding freezing.

4. Under normal conditions, the product remains stable for 6–12 months.

Q1: What is Aluminum Chlorohydrate (ACH) and what are its main applications?

A1: Aluminum Chlorohydrate (ACH) is a highly efficient inorganic polymer coagulant widely used in drinking water purification, industrial wastewater treatment, papermaking, dyeing, and cosmetics. Compared with traditional Polyaluminum Chloride (PAC), it offers higher alkalinity, better stability, and lower residual aluminum..

Q2: What is the difference between Aluminum Chlorohydrate (ACH) and Basic Aluminum Chloride (BAC)?

A2: Both ACH and BAC are aluminum-based coagulants, but ACH has a higher degree of polymerization (alkalinity up to 70–85%), faster hydrolysis, and denser flocs, making it ideal for high-quality water purification. BAC has lower alkalinity and is more suitable for general industrial wastewater or primary treatment processes.

Q3: How effective is Aluminum Chlorohydrate (ACH) in wastewater treatment?

A3: ACH demonstrates excellent charge neutralization and flocculation performance, effectively removing suspended solids, color, and COD. It improves water clarity by 30–50% in papermaking, dyeing, and electronic wastewater applications.

Q4: What raw materials are used to produce Aluminum Chlorohydrate (ACH) and what is its manufacturing process?

A4: ACH is produced using high-purity aluminum hydroxide as the main raw material. It is polymerized through a precisely controlled acid-base reaction, ensuring high alkalinity, stability, and a clear, impurity-free solution.

Q5: What is the optimal dosage of Aluminum Chlorohydrate (ACH) and how should it be applied correctly?

A5: The recommended dosage is 10–30 mg/L, depending on water turbidity and contaminant levels. ACH should be diluted 2–5 times before dosing, then mixed thoroughly in a coagulation tank before sedimentation.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: