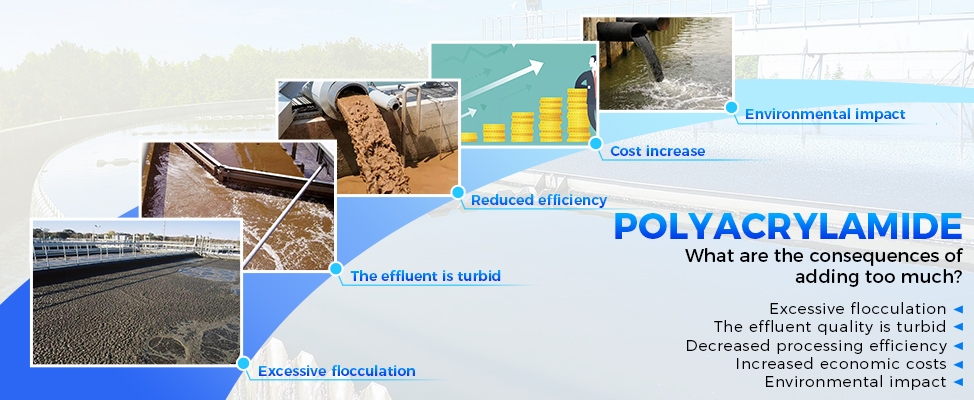

Polyacrylamide (PAM) is a highly effective flocculant widely used in wastewater treatment, sludge dewatering, and industrial effluent treatment. However, overdosing PAM can lead to several problems:

1. Reduced Flocculation Efficiency

PAM works by binding suspended particles into flocs. However, excessive dosing causes PAM molecules to compete with each other, resulting in weak, loose flocs that settle poorly—sometimes even causing re-stabilization and increased water turbidity.

2. Increased Sludge Volume & Higher Costs

Too much PAM leads to bulky, swollen sludge, making dewatering and filtration more difficult. This increases disposal costs and operational expenses.

3. Secondary Water Pollution

Undissolved PAM residues may break down into acrylamide monomers (a toxic substance), posing environmental and health risks.

4. Equipment Clogging & Operational Failures

Excess PAM can clog pipes, pumps, and filter media, increasing maintenance costs and potentially disrupting the entire water treatment process.

PAM sometimes fails to dissolve properly, forming sticky lumps or “fish eyes.” Common causes include:

1. Improper Dosing Method

PAM must be added gradually to water. Dumping it too quickly causes rapid surface hydration, forming gel-like clumps that resist dissolution.

2. Inadequate Mixing

-Too slow: PAM settles and clumps.

-Too fast: Shear force breaks polymer chains, reducing effectiveness.

-Optimal speed: 60-200 rpm for even dispersion.

3. Water Quality Issues (e.g., Hard Water)

High calcium/magnesium levels in hard water react with PAM, slowing dissolution and promoting clumping.

4. Poor Storage Conditions

PAM is hygroscopic (absorbs moisture). Exposure to humidity or damaged packaging causes pre-hydration and clumping.

5. Insufficient Dissolution Time

PAM typically requires 30-60 minutes to dissolve fully. Using it too soon leads to undissolved particles and sticky residues.

-Optimize Dosage: Conduct jar tests to determine the ideal PAM concentration.

-Improve Dissolution: Use the “sprinkle-and-stir” method—add PAM slowly to agitated water.

-Select the Right PAM Type: Choose anionic, cationic, or non-ionic PAM based on water chemistry.

-Proper Storage: Keep PAM in a dry, sealed container to prevent moisture absorption.

While PAM is a powerful water treatment chemical, overdosing reduces efficiency, increases sludge volume, and risks equipment damage. Clumping issues arise from improper dosing, mixing, water hardness, or storage. By optimizing PAM usage and dissolution techniques, you can maximize its performance.

Need expert advice on PAM selection and dosing? Contact our water treatment specialists today!

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: